fierox

Freakzoid

- Joined

- Oct 6, 2013

- Messages

- 85

- Reaction score

- 4

Thx and yes apart from eager to give 3D printing a go i wanted a figure next to Jake's figure aswell

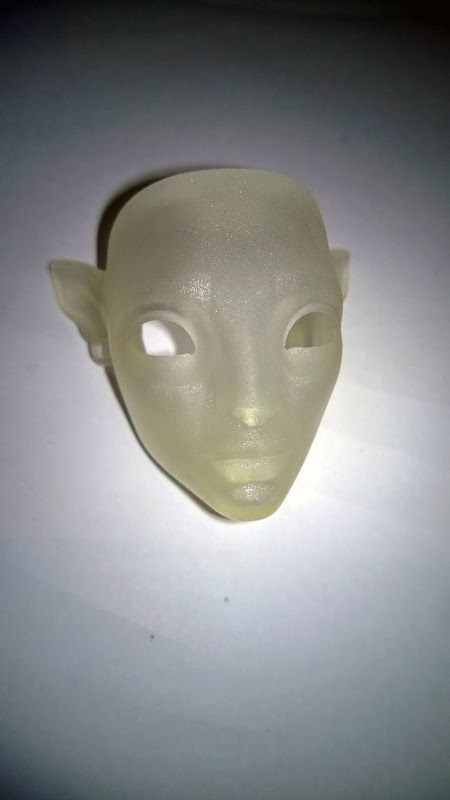

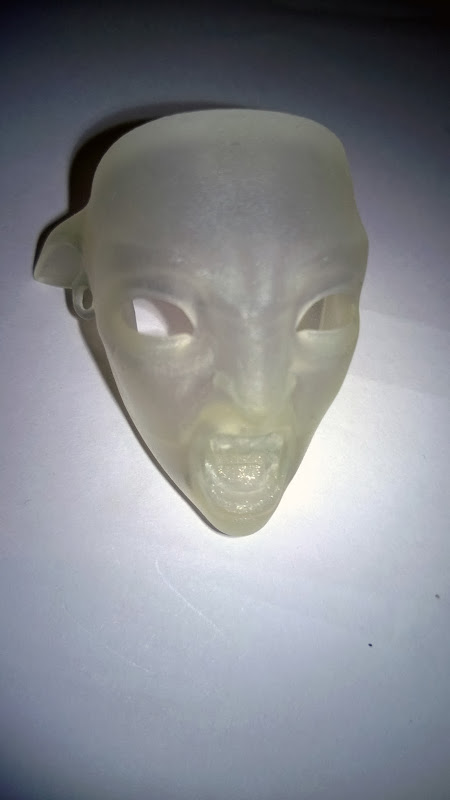

Below is is the model of the figure as how it was send out to get printed.

So the figure's look should be based on this. It will take some time tho because to prevent damage i wont assemble the printed parts (start molding instead). Reason is some parts dont disassemble very well

Below is is the model of the figure as how it was send out to get printed.

So the figure's look should be based on this. It will take some time tho because to prevent damage i wont assemble the printed parts (start molding instead). Reason is some parts dont disassemble very well