robbiethepainter

Super Freak

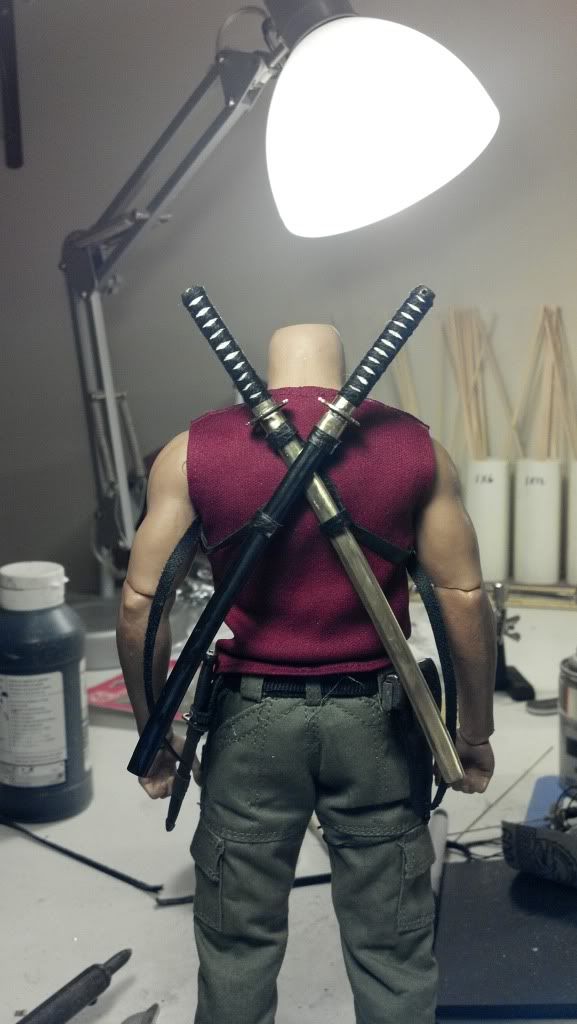

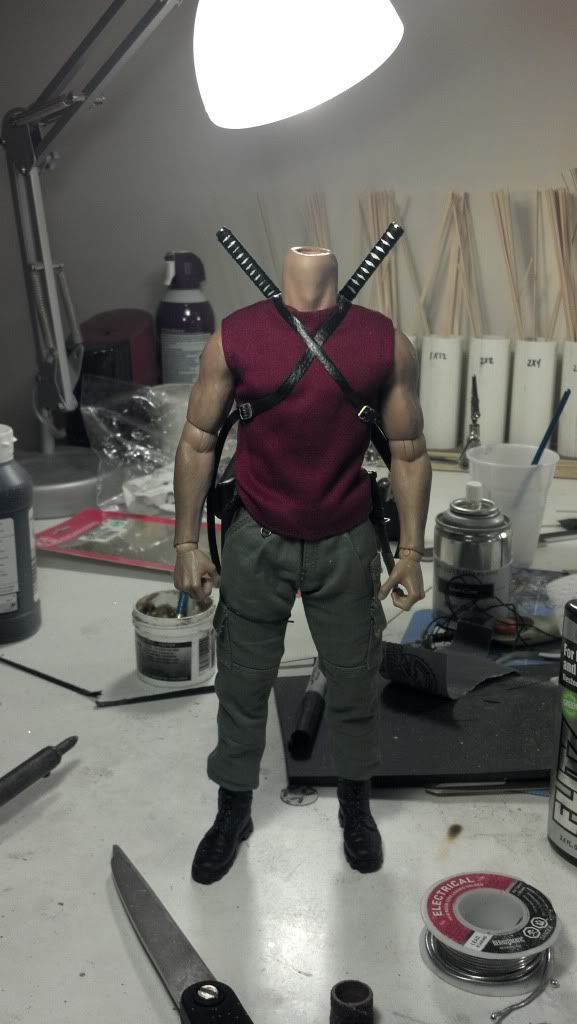

This is how I make swords. I use stainless steel for the blades and different thicknesses of brass strips, sheets and tubing that I buy from my art supply store Blick's. I use steel instead of aluminum because of the ease polishing. I can also use thinner material and its stiffer. I may experiament with aluminum on some thicker blades but for these steel is the best.

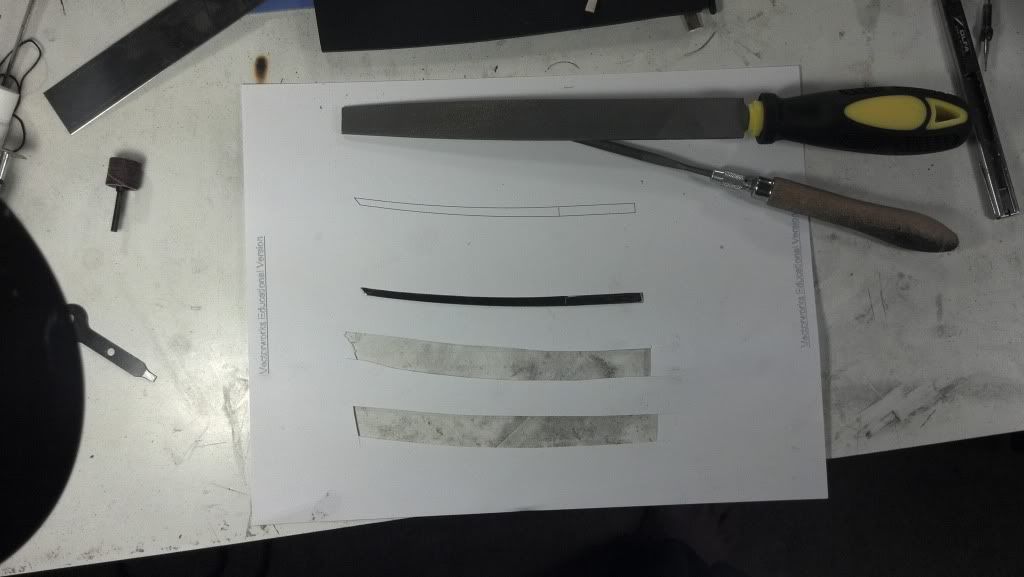

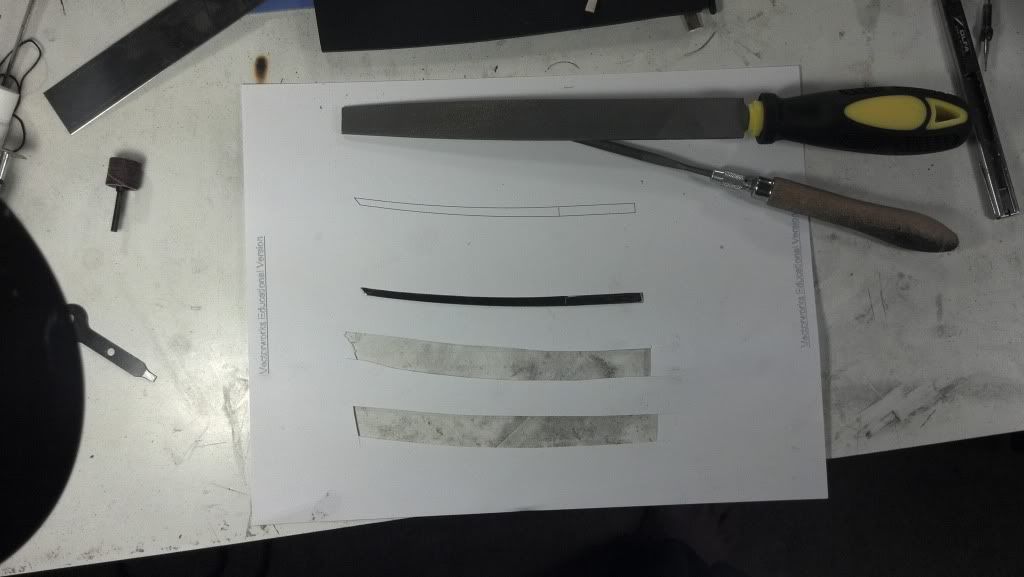

First thing I do is draft out the pattern on the parts. This is really necessary if you are building more then one and they need to match.

Next I cut out the pattern and stick it to the metal using double tack.

I cut along the pattern using a dremel with a cut off disc. Im sure there is a better way but this is what I have at the moment.

I refine the blade with a sanding drum till it fits the pattern I have drawn.

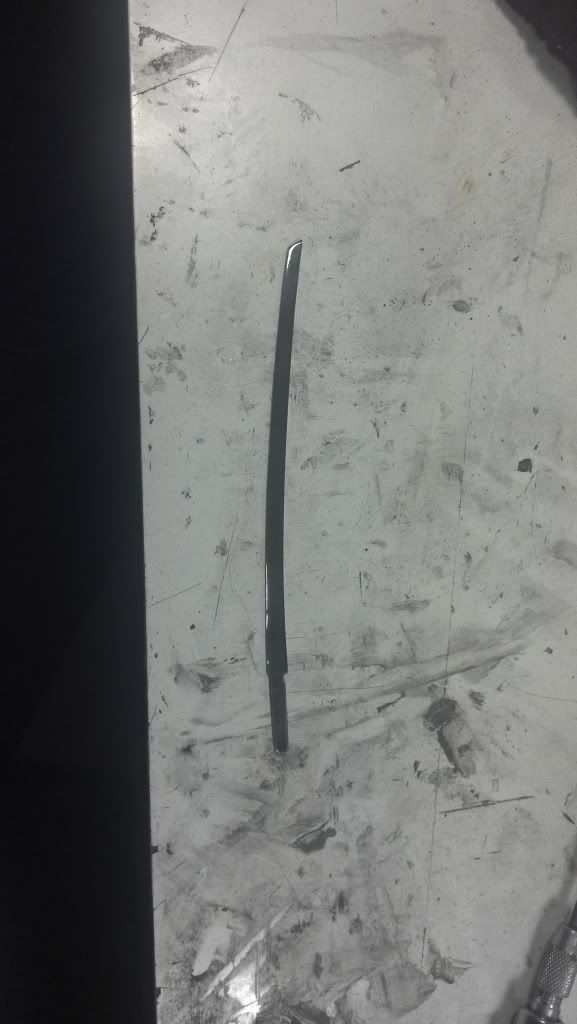

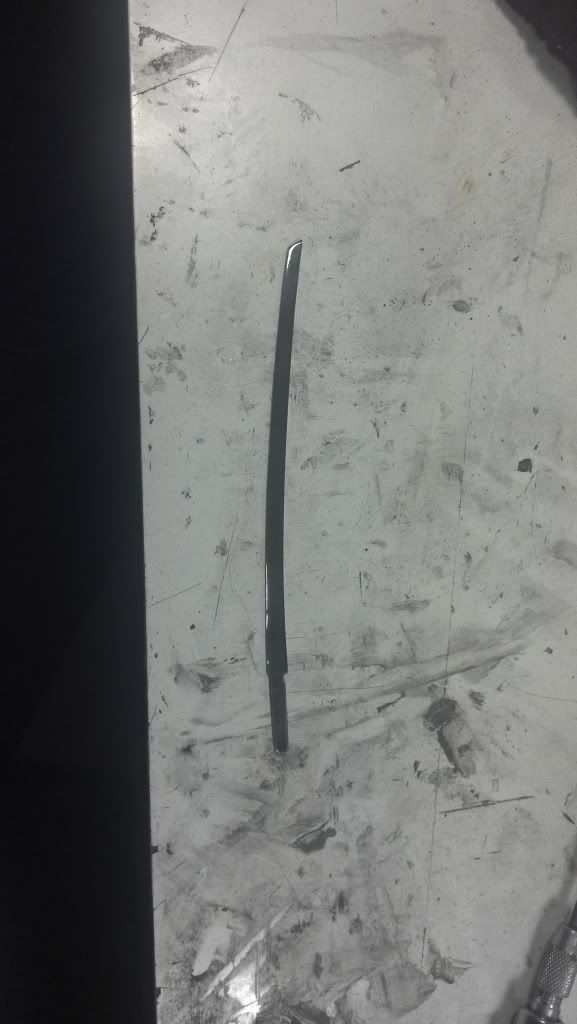

Sand down the surface of the blade with a sanding disk using 220 grit. This even more refines the width of the blade and also rounds the edges. It cleans up the heavy scratches I may have caused during the grinding down of the edges.

Polish the blade using a felt wheel and flitz polish. Be careful because it flings the polish everywhere. I rub it on, spin the wheel away from everything, then go to work polishing.

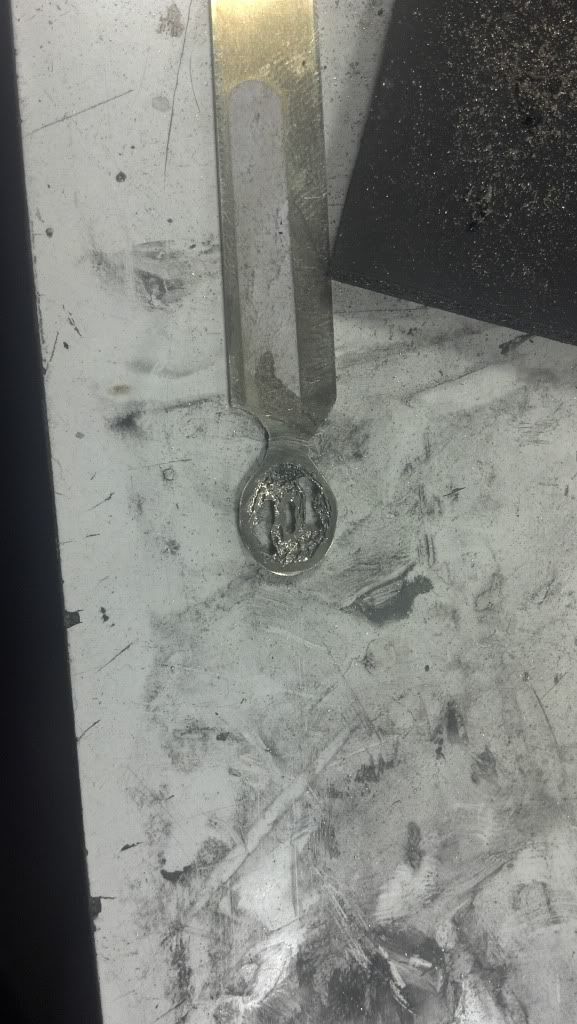

I transfer the design of the tsuba the same way. And then using a toothed grinding like the one listed A.

First thing I do is draft out the pattern on the parts. This is really necessary if you are building more then one and they need to match.

Next I cut out the pattern and stick it to the metal using double tack.

I cut along the pattern using a dremel with a cut off disc. Im sure there is a better way but this is what I have at the moment.

I refine the blade with a sanding drum till it fits the pattern I have drawn.

Sand down the surface of the blade with a sanding disk using 220 grit. This even more refines the width of the blade and also rounds the edges. It cleans up the heavy scratches I may have caused during the grinding down of the edges.

Polish the blade using a felt wheel and flitz polish. Be careful because it flings the polish everywhere. I rub it on, spin the wheel away from everything, then go to work polishing.

I transfer the design of the tsuba the same way. And then using a toothed grinding like the one listed A.